Wuhu Hengxin Cable Co., Ltd

Contact:Mr Dai

Phone: 13955309088

Address: 13955309088@163.com

Address: Jiuhua North Road Electrical Components Industrial Park, Wuhu City, Anhui Province

The medium temperature explosion-proof reinforced self-control temperature tracing cable (self limiting electric heating belt) developed by Wuhu Hengxin Cable Co., Ltd. is widely used for heat tracing insulation, anticoagulation, and antifreeze of pipelines and storage tanks in industrial enterprises such as fire protection, petroleum, chemical, steel, and power. ThisMedium temperatureExplosion proof electric heating cableSuitable for ordinary areas, hazardous areas, and corrosive areas.

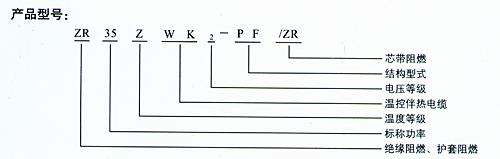

Product model: ZWK (ZXW, ZKW, ZKWZ, ZBW) corresponds to foreign models QTVR series

Temperature Class: Medium Temperature (Z) Series

Structural types: Basic Type (J), Basic Anti corrosion Type (J2), Shielded Explosion proof Type (P), Shielded Anti corrosion Type (P2), Explosion proof Protection Type (PF), Explosion proof Anti corrosion Type (PF2), Explosion proof Protection Anti corrosion Type (Internal and External Full Anti corrosion) (PF) 4

Voltage level: 110V, 220V, 380V, 600V

Nominal power: 35W/m, 45W/m, 50W/m, 60W/m

Cable structure:

1. Copper core wire: 7 × 0.50, 7 × 0.32, 19 × 0.41

2. Conductive plastic layer: ordinary PTC, flame-retardant PTC, fluorine-containing PTC

3. Insulation layer: modified polyolefin, flame-retardant polyolefin, fluorinated polyolefin, perfluorinated material

4. Shielding layer: Tin plated soft round copper wire, covering a density of 80%

5. Sheath layer: modified polyolefin, flame-retardant polyolefin, fluorinated polyolefin, perfluorinated material

Technical indicators:

1. Standard color: Brown

2. Temperature range: maximum working temperature of 105 ± 5 ℃

Maximum exposure temperature 135 ℃

Maximum temperature tolerance: Modified polyolefin 105 ℃, flame retardant polyolefin 105 ℃, fluorinated polyolefin 180 ℃, perfluorinated material 205 ℃

3. Construction temperature: minimum -40 ℃

4. Thermal stability: After cycling back and forth 300 times between 10 ℃ and 149 ℃, the cable's heat generation remains above 90%.

5. Bending radius: 30.4mm at -20 ℃ and 40.6mm at -30 ℃

6. Insulation resistance: When the cable length is 100m and the constant temperature water is 75 ℃; The minimum insulation resistance for testing is 20M Ω, with shielding or explosion-proof protection type. At room temperature of 20 ℃, shake test with 2500VDC between the shielding layer and the conductive wire core for 1 minute, and the minimum insulation resistance is 1200M Ω

Product advantages:

1. The temperature of the heat tracing pipeline is uniform, will not overheat, and is safe and reliable;

2. Save electricity;

3. During intermittent operation, the temperature rise starts quickly;

4. Low installation and operation costs;

5. Easy installation and maintenance;

6. Easy to automate management;

7. No environmental pollution.