Wuhu Hengxin Cable Co., Ltd

Contact:Mr Dai

Phone: 13955309088

Address: 13955309088@163.com

Address: Jiuhua North Road Electrical Components Industrial Park, Wuhu City, Anhui Province

The low-temperature temperature control heat tracing cable (self limiting electric heating belt) developed by Wuhu Hengxin Cable Co., Ltd. is widely used in civil solar energy, geothermal heating, fire protection, petroleum, chemical, steel, power and other industrial enterprises for pipeline and storage tank heat tracing insulation, anticoagulation, and anti freezing. This cable is suitable for ordinary areas, hazardous areas, and corrosive areas.

Product model: DBRK-25-220-P (oilfield specific type)

Temperature Class: Low Temperature (D) Series

Structural types: Basic Type (J), Basic Anti corrosion Type (J2), Shielded Explosion proof Type (P), Shielded Anti corrosion Type (P2), Explosion proof Protection Type (PF), Explosion proof Anti corrosion Type (PF2), Explosion proof Protection Anti corrosion Type (Internal and External Full Anti corrosion) (PF) 4

Voltage level: 220V, 380V

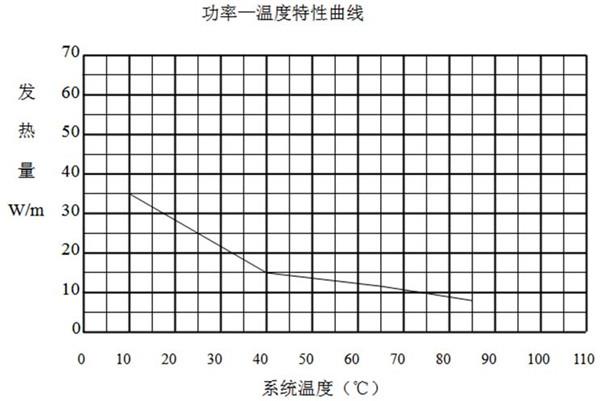

Nominal power: 25W/m

Cable structure:

1. Copper core wire: 7 × 0.50

2. Conductive plastic layer: ordinary PTC, flame-retardant PTC, fluorine-containing PTC

3. Insulation layer: modified polyolefin, flame-retardant polyolefin, fluorinated polyolefin, perfluorinated material

4. Shielding layer: Tin plated soft round copper wire, covering a density of 80%

5. Sheath layer: modified polyolefin, flame-retardant polyolefin, fluorinated polyolefin, perfluorinated material

Technical indicators:

1. Standard color: Black

2. Temperature range: maximum working temperature of 85 ± 5 ℃; Maximum temperature tolerance: Modified polyolefin 105 ℃, flame retardant polyolefin 105 ℃, fluorinated polyolefin 180 ℃, perfluorinated material 205 ℃

3. Construction temperature: minimum -40 ℃

4. Shielding layer: Tin plated soft round copper wire, covering a density of 80%

5. Sheath layer: modified polyolefin, flame-retardant polyolefin, fluorinated polyolefin, perfluorinated material

Product advantages:

1. The temperature of the heat tracing pipeline is uniform, will not overheat, and is safe and reliable;

2. Save electricity;

3. During intermittent operation, the temperature rise starts quickly;

4. Low installation and operation costs;

5. Easy installation and maintenance;

6. Easy to automate management;

7. No environmental pollution.