Wuhu Hengxin Cable Co., Ltd

Contact:Mr Dai

Phone: 13955309088

Address: 13955309088@163.com

Address: Jiuhua North Road Electrical Components Industrial Park, Wuhu City, Anhui Province

Wuhu Hengxin Cable Co., Ltd. is a professionalElectric heat tracing manufacturerWe produce various types of self limiting temperature electric heat tracing belts, constant power electric heat tracing belts, solar electric heat tracing belts, explosion-proof electric heat tracing belts, anti-corrosion heat tracing belts, flame-retardant heat tracing belts, heat tracing sampling composite pipes, cables, and various supporting equipment; Provide users with solutions for tank and pipeline electric heat tracing insulation, product manufacturing, engineering installation, and after-sales service.

HBL typeparallel connectionThe constant power electric heating belt is referred to as a parallel type due to its multiple heating nodes connected in parallel along the entire lengthConstant power electric heating belt.

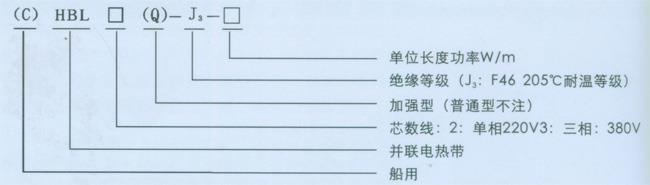

1 Product model:

Example: a HBLtwo (Q) - Jthree-thirty represents a single-phase reinforced constant power parallel electric heating belt with a power of thirtyW per meter

b. HBLthree (Q) - Jthree-forty represents a three-phase power parallel heating belt with a power of fortyW per meter.

two. Product structure and working principle

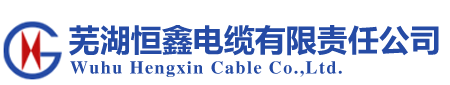

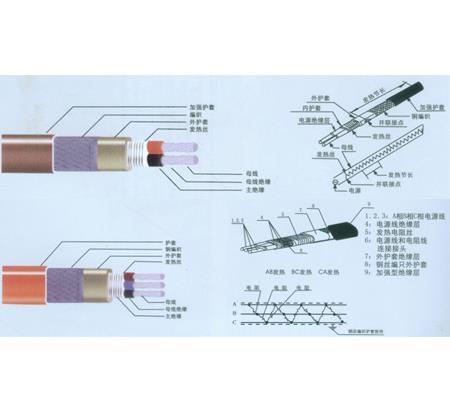

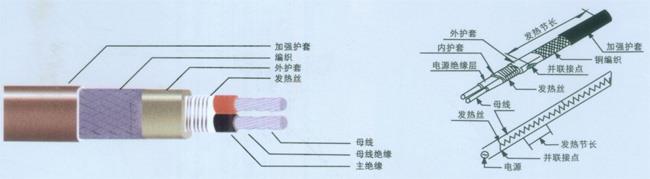

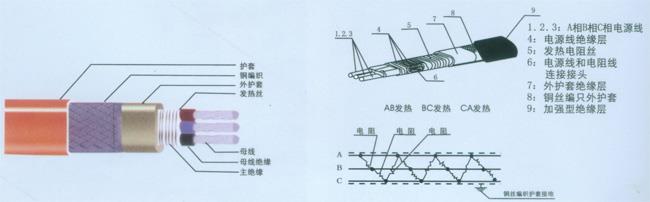

(1) Constant power parallel electric heating belt structure (see Figure 1 and two)

Figure 1: Schematic diagram of HBLtwo constant power parallel electric heating belt structure

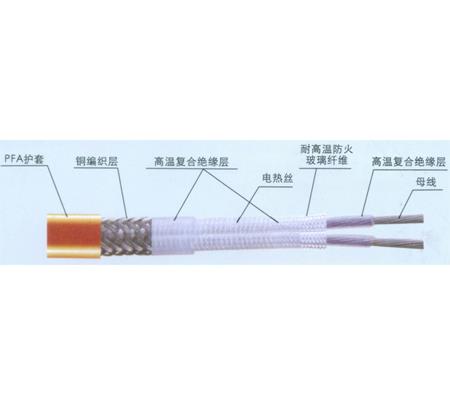

Figure 2: Schematic diagram and electrical schematic of HBL2 constant power parallel electric heating belt structure

(2) Working principle

The power bus consists of two or three parallel insulated copper wires, which are wrapped with heating wires on their surfaces and connected to the bus at regular intervals (i.e. the length of the heating section) to form a continuous parallel resistor. After the bus is powered on, each parallel resistor heats up, thus forming a continuous heating strip.

three. Product specifications and main technical indicators (see Table 1):

project model | Rated Voltage (V) | Rated power (W/m) | Maximum length for bidirectional use (m)) | Maximum temperature resistance ℃ | Explosion proof mark | Fluid maintenance Temperature ℃ |

HBL2(Q)-Jthree-ten | two hundred and twenty | ten | four hundred and fifty | 205° | ellTthree | 1thirty℃ |

HBL2(Q)-Jthree-20 | two hundred and twenty | 20 | three hundred and fifty | 205° | ellTthree | 120℃ |

HBL2(Q)-Jthree-thirty | two hundred and twenty | thirty | three hundred | 205° | ellT3 | 95℃ |

HBL2(Q)-J3-forty | two hundred and twenty | forty | two hundred and sixty | 205° | ellT3 | 75℃ |

HBL2(Q)-J3-thirty | three hundred and eighty | thirty | six hundred | 205° | ellT3 | 120℃ |

HBL2(Q)-J3-forty | three hundred and eighty | 40 | five hundred and thirty | 205° | ellT3 | ten0℃ |

HBL2(Q)-J3-fifty | three hundred and eighty | fifty | four hundred and sixty | 205° | ellT3 | 80℃ |

HBL2(Q)-J3-sixty | three hundred and eighty | sixty | four hundred | 205° | ellT3 | sixty℃ |

#Fluid maintenance temperature: refers to the higher process temperature that the medium inside the pipeline needs to maintain, generally not exceeding the values specified in this table# 15W/M, 25W/M, 35W/M, 45W/M, 55W/M, and electric heating belts are non-standard. You can consult our company to order and supply according to your needs. Special working voltages are 24V, 35V, 45V, 55V, and 110V.

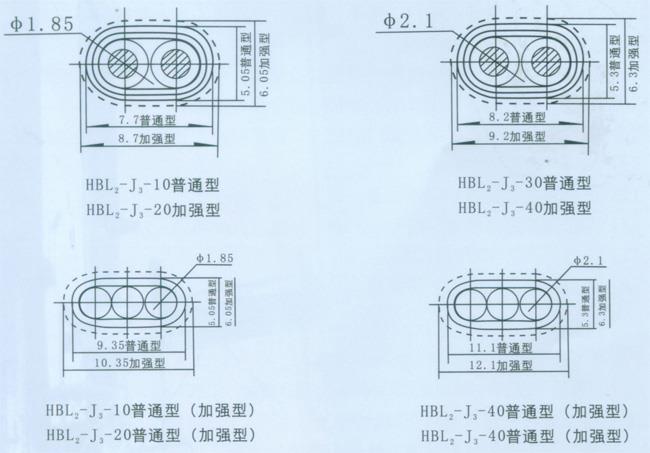

4. The cross-sectional dimensions of the product are shown in Figure 3

Figure 3: Sectional dimensions of HBL type electric heating belt

5. Product Features

The heat generation per unit length of a constant power parallel electric heating belt is constant, and the longer the electric heating belt used, the greater the total power output. The electric heating belt can be cut to any length required on site. In addition, due to its flexibility, the electric heating belt can be easily attached to the surface of the pipeline. The metal shielding net on the outer layer of the electric heating belt can prevent static electricity and ground it. It not only improves the overall strength of the electric heating belt, but also plays a role in heat transfer and dissipation.

When using a constant power parallel electric heating belt in conjunction with a temperature controller. It can maintain the temperature of the medium in the pipeline or heating element.

Enhanced typeConstant power electric heating beltIt is an insulation layer wrapped around the outer layer of a regular electric heating belt, and the rest of the structure is the same as that of a regular electric heating belt. The main characteristics of reinforced electric heating belts are that ordinary electric heating belts have high mechanical strength and strong anti-corrosion ability, but slightly lower thermal conductivity. They are mainly used in underground pipelines and corrosive gas environments. Due to the limited cross-sectional area of the busbar, there is a certain limit to the length when the single point power supply is output unidirectionally. When the single point power supply is output bidirectionally, the length can be doubled (see Table 1 and Figure 4). If a longer pipeline is required for heat tracing, multi-point power supply can be used, or our company's HCL series electric heating belt can be used (see introduction on the following page).

Figure 4: Bidirectional output diagram of single point power supply

In addition to the characteristics of single-phase electric heating belts, three-phase electric heating belts also have the advantages of long length, good heat uniformity, and the ability to balance the load of the power grid.

Installing electric heating belts and controlling electrical appliances generally has overload, short circuit, leakage, and overheating protection.

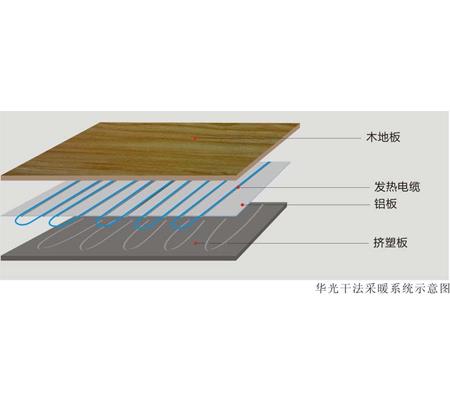

6. Product application scenarios:

Electric heating belts are mainly used for antifreeze and insulation of pipelines, valves, pump bodies, storage tanks, reaction towers, instrument boxes, etc., or to maintain the process temperature of instrument pipelines. The specific application scenarios mainly include:

(1) Under normal circumstances, the use of low solidification pipelines with continuous flow can prevent the medium from solidifying due to the cessation of flow.

(2) The tracing and insulation of liquid pipelines that require strict control of operating temperature.

(3) Antifreezing of water pipelines and valves in cold and freezing areas, as well as antifreeze of drainage pipes, extraction pipes, and condensation pipelines.

(4) Antifreezing of offshore platform pipelines.

(5) Thermal insulation for general pipelines and instruments.

(6) Wellhead oil production vertical shaft heat tracing (replacing water protection sleeves), sewage well heat tracing.

(7) Airport runway anti icing and snow freezing.

(8) Antifreeze curing of concrete products.

7. Explosion proof instructions:

Electric heating belts are designed and manufactured in accordance with GB3836.1-2000 and GB3836.3-2000, which are the "General Requirements" for explosion-proof electrical equipment used in explosive environments and the requirements for increased safety electrical installations. The explosion-proof level is "ell T3-T6", and the explosion-proof certificate numbers are CNEX02 and 433U. The product has flame retardancy and, when paired with safety enhancing electrical accessories, is suitable for use in explosive gas mixture "T3-T6" group locations in Zone 1 and Zone 2 of factories that are not directly impacted by external forces.