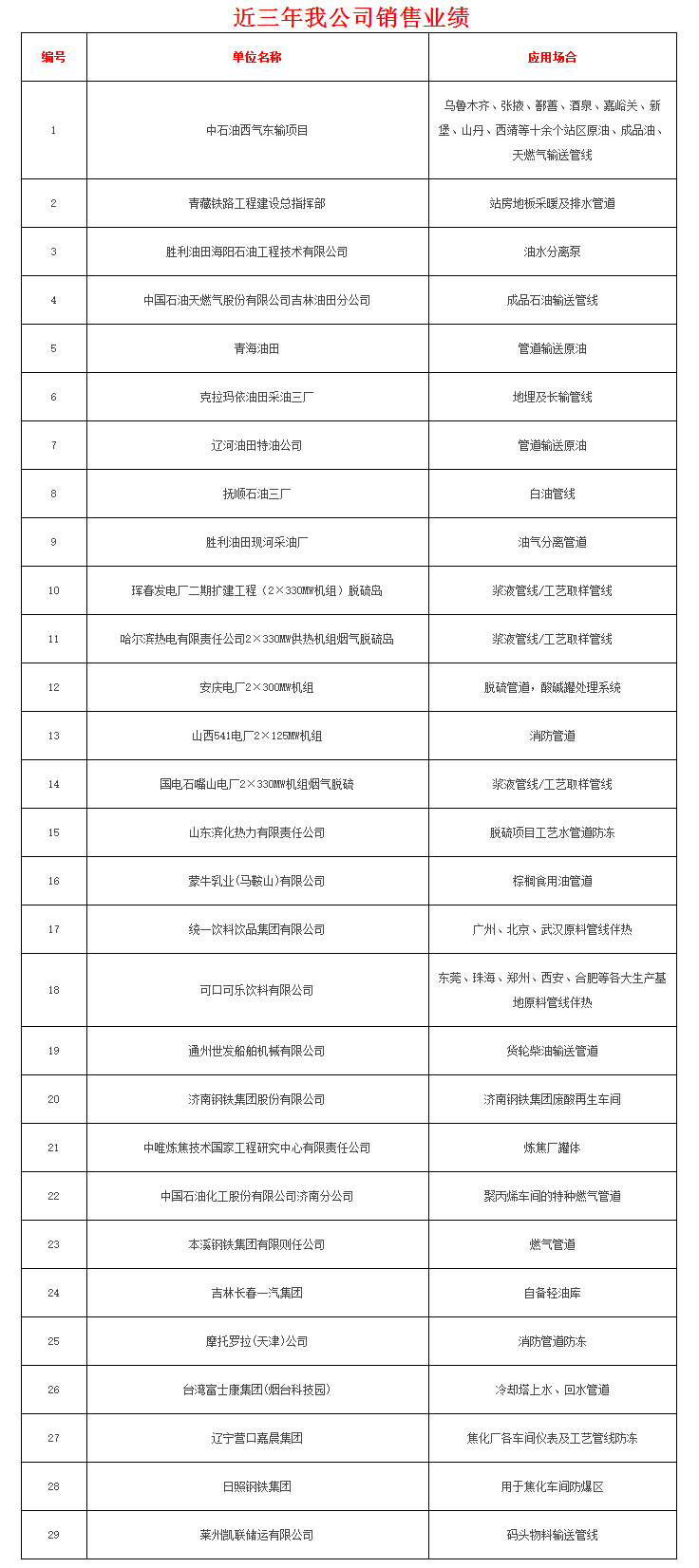

Wuhu Hengxin Cable Co., Ltd

Contact:Mr Dai

Phone: 13955309088

Address: 13955309088@163.com

Address: Jiuhua North Road Electrical Components Industrial Park, Wuhu City, Anhui Province

Alkali solution pipeline antifreeze and heat tracing:

1、 Overview

As an effective pipeline insulation and antifreeze solution, heat tracing has been widely used in thermal power plants. Its working principle is to dissipate a certain amount of heat through a heat tracing medium, and supplement the heat loss of the traced pipeline through direct or indirect heat exchange, in order to achieve the normal working requirements of temperature rise, insulation or antifreeze. For a long time in the past, steam tracing has always been the main insulation method in the vast majority of thermal power plants. Its working principle is to dissipate heat through steam tracing pipes to supplement the heat loss of the insulated pipes. Due to the difficulty in controlling the heat dissipation of steam, its insulation efficiency remains at a relatively low level. Moreover, due to the fact that the pipelines that require heat tracing in power plants are generally dominated by instrument pipelines, process pipelines, and chemical pipelines, which are relatively complex, laying steam heat tracing pipelines is very inconvenient. In addition, during winter operation, steam tracing pipelines often experience "running, emitting, dripping, and leaking" phenomena. Every winter, the maintenance department of the power plant has to spend a lot of manpower and material resources on pipeline insulation to ensure the safe operation of the power plant in winter.

In the 1970s, the US energy industry proposed the idea of using electric heat tracing to replace steam heat tracing. In the late 1970s and early 1980s, many industrial sectors, including the energy industry, widely promoted electric heat tracing technology, replacing steam heat tracing with electric heat tracing. The development of electric heat tracing technology has evolved from traditional constant power heat tracing to self controlled temperature electric heat tracing with conductive plastics as the core.

1. Principle and application of self controlled temperature electric heating

The self controlled temperature electric heating scheme is mainly achieved through the automatic temperature control of the self controlled temperature electric heating cable. The automatic temperature control heating wire consists of a conductive wire core (PTC layer) and two parallel busbars extruded with an external insulation layer, a metal shielding layer, and an anti-corrosion sheath layer. The conductive core tape, which is made by mixing resin and conductive carbon particles with various additives and specially processed, is the heating core. When conductive carbon particles are connected by chemical bonds at a certain ambient temperature to form a conductive network for power flow, the heating wire begins to heat up after the power is turned on; When the temperature is high, the conductive carbon layer undergoes micro molecule expansion, causing the carbon chains to gradually separate, resulting in a smaller network, a sharp increase in resistance, a decrease in conduction current, a gradual decrease in heating wire power, and a decrease in heat generation. The entire system is in a stable state, which is a relative equilibrium state. When the ambient temperature drops, the plastic returns to a state of micro molecule contraction, and the carbon particles are connected to form an electrical circuit, causing the heating power of the heating wire to automatically increase. Due to the fact that the entire temperature control process is automatically adjusted by the material itself, the controlled temperature will not be too high or too low. Therefore, the excellent characteristics of electric heat tracing are incomparable to other heat tracing systems. The automatic temperature electric tracing system is applied in the insulation and antifreeze process of industrial pipelines. In response to the special technical requirements of power plant tracing, the automatic temperature electric tracing system can accurately and conveniently play the role of insulation and antifreeze, providing strong guarantee for the good operation of power plants in winter.

The DWK2-P explosion-proof temperature control heat tracing cable used by our company in the Anqing Power Plant Phase I (2 × 300MW alkali tank heat tracing system) project is a temperature control heat tracing cable designated for use by Anhui Electric Power Design Institute. Please refer to the schematic diagram of the electric heating belt configuration design by Anhui Electric Power Design Institute as follows:

With the development of industrial technology, electric heating belts have been applied in various fields. Some large oil fields, refineries, pipelines, storage tanks, etc. have already used electric heating belts. However, most of the pipeline insulation and heat tracing still use steam. Compared with electric heating belt heat tracing:

1. Steam tracing: Pipeline tracing consumes a large amount of steam, while process pipeline tracing consumes a large amount of steam

Electric heating tracing

2. The maintenance cost of the heat tracing pipeline includes patrol inspection, maintenance updates, and various maintenance costs. Due to the susceptibility of instruments in the fertilizer plant area to corrosion

3. Self controlled electric heating wire is an energy-saving measure because it can sense the temperature of the pipe wall (medium) and self regulate the heat generation. Steam tracing can only utilize a portion of the thermal energy, and a large amount of thermal energy changes from high-grade to low-grade, which cannot be utilized and is wasted

In the chemical production process, steam tracing is a traditional insulation method for fluid material transportation and storage. However, due to the steam temperature being much higher than the temperature range that the material needs to maintain, improper temperature adjustment can cause local material overheating. Moreover, the insulation and maintenance of the steam companion condensate pipe are not good, which can sometimes freeze and affect production. Especially when transporting and storing highly corrosive materials, it is easy to cause local corrosion of pipes, seriously affecting normal production. The self-control electric tracing system of RAYCHEM company in the United States is applied to industrial pipeline insulation and antifreeze technology, which can accurately maintain process temperature and eliminate corrosion caused by local overheating of pipelines.

The temperature controlled heating cable is equipped with an automatic adjustment of output power by the heating system, so it will not burn out due to its own heat generation. However, it is a new generation of energy-saving constant temperature heater that compensates for the actual need for heat. Low temperature state, fast start, uniform temperature, as each part can be automatically adjusted according to the temperature changes at its heat tracing location. Easy to install, easy to maintain, 24/7 service, high level of automation, low operating and maintenance costs. Safe and reliable, versatile, non polluting to the environment, and long lifespan.

Fire pipeline heat tracing and antifreeze:

Special self-control temperature electric heating belt for fire protection pipeline sprinkler system in building basement

The ZRDWK-J ZRDWK-PF series of automatic temperature control electric heating belts produced by the company are used in the fire pipe sprinkler system of the underground garage of the Beijing Oriental Plaza fire engineering project. The ZRDWK-J ZRDWK-PF has been widely used in the anti freezing and heat tracing of the fire pipes in Beijing Hua'an Beihai by the installation company of Beijing Construction First Bureau. Its good performance and stable performance have solved many users' winter heat tracing and anti freezing problems.

The increase in the proportion of public facilities in buildings and the increase in external equipment have exposed more and more complex piping systems to relatively open spaces. Cold weather can cause damage to this part of the pipeline at any time, and this damage is undoubtedly fatal to the overall building pipeline. In addition, the improvement of safety standards for important pipelines in buildings has made pipeline antifreeze systems play an increasingly important role in buildings.

Self controlled electric heating belt (without temperature control) - anti freezing and insulation, characterized by energy saving, easy use, good temperature control and insulation effect. The traditional method is to use steam pipeline heating, which is labor-intensive, low thermal efficiency, and high energy consumption.

Self controlled heating belt is a flat and soft strip that is easy to bend, wrap or lay flat on components such as pipelines, valves, pump bodies, storage tanks that require heating, insulation, and antifreeze. It has the characteristics of heating, automatic insulation, and temperature limiting. The maximum maintenance temperature for constant temperature is 65 ± 5 ℃. We will provide a complete set of products and technical services

With the increase in the proportion of public facilities in buildings and the addition of external equipment, the originally complex pipeline system is increasingly exposed to relatively open spaces. So the improvement of safety standards for important pipelines in buildings has made pipeline antifreeze systems play an increasingly important role in buildings. On the one hand, while paying attention to environmental protection, an electric heat tracing system is also needed for anti freezing and insulation to maintain the water in the pipeline from freezing in winter.

At present, in the selection of products for fire electric heating belts, it is widely recognized that temperature controlled heating cables are one of the best products for widespread use. As early as the 1980s, the American company RAYCHEM successfully developed intelligent insulation and heat tracing products, also known as self controlled temperature tracing cables or self limited temperature heating belts. Our company's product is a research achievement of the national "Ninth Five Year Plan" key scientific and technological research project - temperature controlled heating cables (self limited temperature electric heating belts). It has the advantages of long service life, low starting current, good memory performance, and low annual attenuation rate, and is highly praised by users!

Temperature controlled heating cable is a nationally promoted product, welcome to use it!

Safety - Provides you with maximum safety guarantee. PTC characteristics and unique structure ensure that the output power of the cable responds quickly to changes in ambient temperature, without the worry of local overheating and fire. Convenient - Cut into any length according to needs. Continuous parallel conductor structure and uniform heating medium distribution, CI-HEATER has constant power output per unit length, so it can be cut on site according to the required length.

Far infrared low-temperature radiation electric heating belt for intelligent ground heating with electric heating

1. Overview:

Electric floor intelligent heating with far-infrared low-temperature radiation temperature control electric heating belt is specially designed for electric floor heating. It can also be used in road icing and snow and other occasions, suitable for ordinary areas, dangerous areas, or explosion-proof areas in corrosive areas.

2. Structure:

(1) Stranded layer: made of tinned soft round copper wire twisted together;

(2) Core tape layer: extruded from a semi conductive material with positive temperature effect on two parallel twisted wires;

(3) Insulation layer: made by extruding specially made polyethylene or flame-retardant polyolefin;

(4) Shielding layer: woven from tinned soft round copper wire: (Some manufacturers use aluminum alloy wire to save money, but this incorrect usage is due to the fact that the electrical resistivity of alloy wire is about 3-5 times that of tinned soft round copper wire. It can be imagined that any grounding or short circuit phenomenon will pose a threat to property and personal safety. It is recommended that users do not use it.)

(5) Protective layer: Polyolefin or flame retardant polyolefin or fluorine bis (VI) and fluorine tetra (VI).

3. Characteristics:

1. Uniform temperature

Electric heating ground emits low-temperature far-infrared radiation from bottom to top. Two types of automatic control, product self control+auxiliary temperature control.

2. Cleanliness, hygiene, and health care

The low-temperature and far-infrared characteristics of electric heating belts emit beneficial far-infrared radiation for the human body, which plays a role in healthcare. Heating is mainly provided by far-infrared radiation, and the air is clean, pollution-free, fresh, and pleasant.

3. Reasonable distribution of room temperature

The ideal heating temperature distribution layer should be "warm enough and cool at the top". When the temperature under the feet is low, the whole body will feel cold. The far-infrared self-control temperature electric tropical ground heating system is the system closest to the ideal heating temperature distribution layer.

4. Energy conservation

Due to the reasonable indoor temperature distribution and the temperature control characteristics of the electric heating belt itself, this product is the only most energy-efficient and intelligent point heating element. Combined with intelligent temperature controllers installed in each room, this series is 30% -50% more energy-efficient than traditional heating systems.

5. Safe and convenient

Electric heating belts can be cut, crossed, and overlapped without the risk of overheating or burning out the heating system due to the failure of the temperature controller and covering the electric heating floor. The product has flame retardancy and an insulation resistance of ≥ 100M Ω, ensuring absolute safety.

6. Long service life

The electric heating belt is made of fluorine-containing materials, and the protective layer is also made of fluoroplastic commonly known as "Plastic King", ensuring a service life of more than 50 years for the system. The system is completely enclosed and no components will be damaged by human factors. The electric heating ground is maintenance free, saving manpower and material resources.

7. Does not take up space for use

The heating system basically does not take up space and increases the usage area by 3% -5% compared to traditional heating. It does not affect various decorations and appliance arrangements, and has strong compatibility.

4. Construction and installation:

1. Process flow

Sweep the floor → Dry lay polystyrene insulation board → Lay composite aluminum foil → Lay steel wire mesh → Heat cable detection → Tie heating → Cable → Heat cable detection → Pour concrete floor → Check level → Cable detection → Circuit connection → System debugging.

2. Circuit schematic and engineering installation diagram:

Solar series

instructions:

When using this product for insulation and thawing of solar water heaters, remember to configure a leakage protection switch.

The maximum length of the electric heating belt is related to the load size and the cross-sectional size of the conductive core of the electric heating belt. If the pipe length exceeds 10 meters for heat tracing, it is necessary to refer to the design manual for thermal design selection to avoid misuse.

The tail end of the electric heating belt should use a flame-retardant heat shrinkable tube fireproof envelope that has been irradiated and cross-linked. If insulating tape is used, it will also short-circuit over time. Huaguang brand electric heating belts are equipped with dedicated heat shrinkable sleeves for users.

The series of electric heating belts specifically designed for solar water heaters are made of nano conductive materials and polymer composites, evenly extruded on two parallel metal wires, and crosslinked by irradiation. They have the advantages of rapid heating in cold environments, low starting current, automatic adjustment of output power according to the temperature of the water heater pipeline, flexible length cutting, no high temperature overheating phenomenon, easy installation and maintenance, etc. They are the preferred product for effectively preventing freezing of solar water heater pipelines.

The civil hot water pipeline electric tracing system can quickly, conveniently, and reliably deliver hot water to every part of the system. After adopting electric heat tracing, the hot water system will no longer require the original circulation loop system. Only the self regulating heat tracing wire needs to be laid on the hot water pipeline. It can maintain a constant temperature at every point along the pipeline, ensuring constant temperature of the main and branch pipes, truly achieving instant use of hot water. The self-adjusting electric heating wire can be cut, spliced, and the circuit length can be determined according to the on-site situation at will. At the same time, it can also be connected in three ways. Installation is simple and convenient. The heating element of the electric heat tracing system is a conductive plastic that has been irradiated and crosslinked. The power of the heat tracing wire changes with temperature. When the temperature is low, the heat generation is large and quickly generates heat, meeting the requirements of insulation; When the temperature is high, the heat generation is small, achieving the goal of energy conservation. The self regulating performance of the heating wire allows it to overlap and wrap, and automatically adjust the output power according to the water temperature and room temperature to prevent overheating of the water temperature. By adopting an electric heat tracing system, the hot water pipeline is greatly reduced, and the heat loss is also greatly reduced, which has a significant energy-saving effect.

advantage:

1. The temperature of the heat tracing pipeline is uniform, will not overheat, and is safe and reliable;

2. Save electricity;

3. During intermittent operation, the temperature rise starts quickly;

4. Low installation and operation costs;

5. Easy installation and maintenance;

6. Easy to automate management;

7. No environmental pollution.

Solar series

Product Name Model Power W/m · 10 ℃ Maximum Maintenance Temperature ℃ Maximum Endurance Temperature ℃ Minimum Installation Temperature ℃ Maximum Usage Length m

Solar special belt HG 10,15,25,30 65 ± 5 85-20 30

HG-1 10,15,25,30 65±5 85 -20 30

HG-2 10,15,25,30 65±5 85 -20 30

HG-3 10,15,25,30 65±5 85 -20 30

HG enhanced type 10,15,25,30 65 ± 5 85-40 50

Our company's products are suitable for the following fields:

| power industry | Refining industry | petrochemical industry | chemical industry | Fire protection system |

| High pressure water supply Discharge and emptying of sewage Instrument steam Degassing high-pressure condensation Acid alkali storage point for heavy oil Huoyou Road | Benzene distillation Ammonia hydrogenation cracking Caustic soda coking Heavy oil wax Sulfur sulfide Xylene asphalt Gas or fluid heavy oil | Phthalic anhydride Acrylic acid and grease polyvinyl chloride Styrene and polystyrene Industrial gases polyolefin terephthalic acid | Isopropyl sulfate Phenol formaldehyde Bromic acid chlorine gas | Underground garage sprinkler system Fire Hydrant Fire pipeline Roof water tank |

| Pharmaceutical and health products | construction | Onshore/offshore oil fields | Food and beverage industry | Pulp and paper products |

| Binary fatty acid Aromatic hydrocarbons containing substituents Long-chain fatty acids glycol | Hot water system Floor insulation system Roof snow melting system Snow melting system Gas storage tank antifreeze system Air conditioning delivery pipeline | Water purification system Seawater treatment system Instrument antifreeze Antifreezing of oil and gas pipelines Hot water system | Chocolate conveying pipeline Edible oil Beer and software ingredients Production process Fat | Process water and drinking water Fire water instrument pipeline Adhesive glue |

| Paint industry | Water soluble coating for cooling water system | Public utility equipment | Condensation system process gas pipeline fuel |