Contact Us

Wuhu Heng Xin Cable Co., Ltd.

Susie: 13695533065

Email: info@ahhengxincable.com

Sales Hotline: 0553-3837700, 3832212

Address: Anhui Province Wuhu Nine North

China Road electrical Components Industrial

Parkl

| Chapter One: Installation and test of temperature-controlled heating cable | |

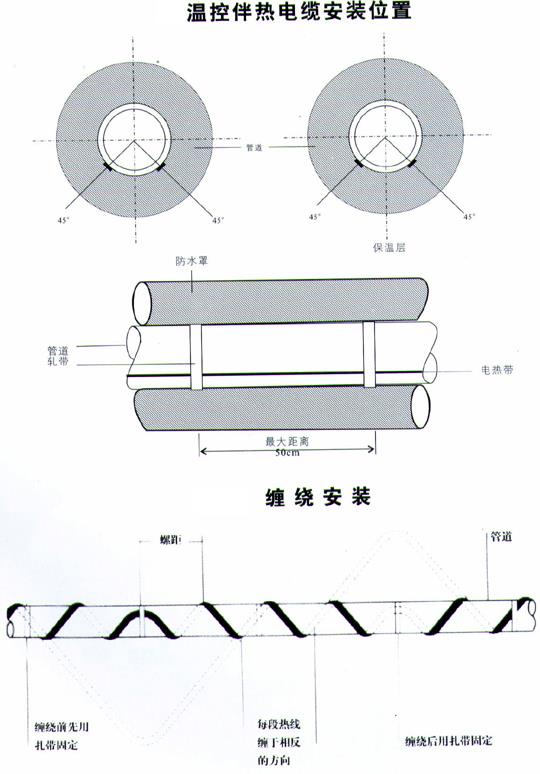

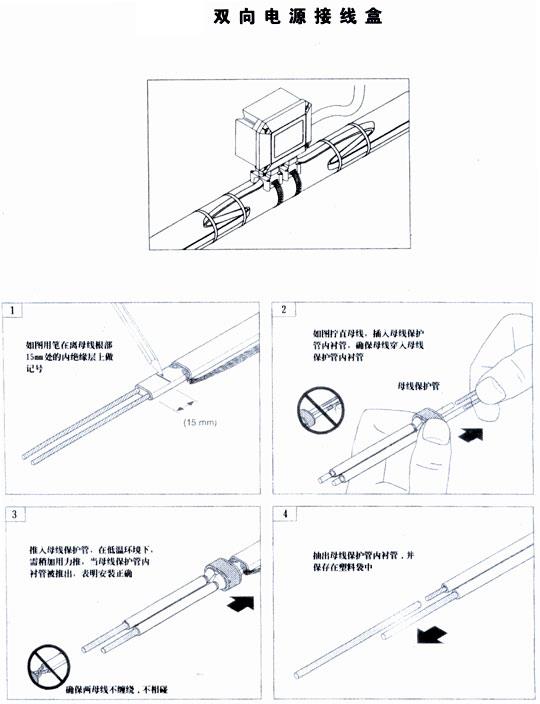

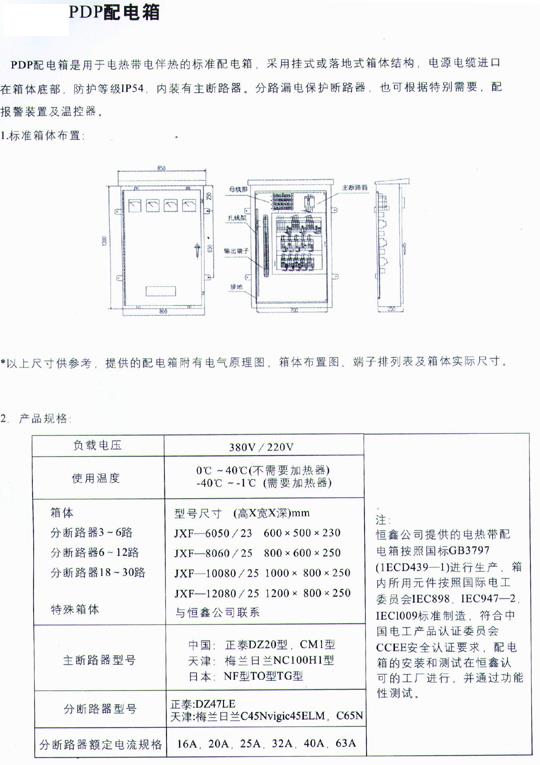

(i) Design drawings There should be a complete design plan before construction, which should include the following information: 1, line number, power supply point with a long square. 2, the line of the required type and length of the Electric tropics. (Unit: M) 3, the length of the pipeline per metre of electric heating required length (unit: m) that is winding coefficient 4, each valve needs to use the tropical length of electricity. (Unit: M) 5. Accessory List of accessory materials for heating system. 6, Temperature control system Accessories list. 7, the construction of the required materials list. 8, design consideration parameters and the use of insulation material specifications. (ii) preparatory work before construction (A) Piping systems 1, piping systems and equipment have been completed construction. 2, Antirust anti-corrosion coating has been dry thoroughly. 3, piping system construction specifications and design drawings are consistent. 4. File all burrs and angles. (B) Electric Tropics and accessories 1. Whether there is damage to the surface of the electric tropics. 2, the electric tape insulation performance is good (requires the use of shaking table in the 1000VDC test insulation resistance for ≥20mω). 3, the Electric Tropics and all parts of the model and design requirements are consistent. (C) On-site preparation 1. Place a coil of electric tropics and reel on a bracket and place it near one end of the line. 2, along the pipeline to the heating of the tropics, and to avoid: * Place the Electric tropics on the burr and the angle of interest. * Pull the electricity tropics hard. * Put on the electric belt with pedal or heavy weight. (iii) A single electric-tropical construction method 1, glass fiber pressure sensitive tape or aluminum tape every about 50Cm will be fixed to the electric heating pipe. 2. As far as possible, the electric heating will be attached to the lower 45 degree side of the pipe. 3, in the line of the first power supply point and the end of each reserved 1m long electric belt. 4, as shown in the design diagram [winding coefficient] wiring (coefficient of integer should be flat to reduce contact). 5, all heat sinks (such as stent, valve, flange, etc.) should be in accordance with the requirements of the design plan required to reserve the length of the Electric tropics, this section of the electric tropical winding on the main body and fixed. The following points should be noted: * Thermal body should be designed to the length of the electric tropical. * The electric tropics may overlap or cross each other. * Winding method should be as far as possible to remove the heatsink when necessary to repair or replace without damaging the electric tropics or affect other lines. * In the use of two-pass or tee accessories, the electric tropics should be reserved 40cm length. (d) Spiral winding such as winding coefficient of 1.4, that is, 5m pipe need cloth 7m of the electric belt, the construction of the first 7m long electric belt fixed at both ends of a length of 5m pipeline, and then the relaxation of the electric tape winding in the pipeline, and fixed. (v) Multi-root electric-tropical construction method 1. The design diagram indicates that the winding coefficient is (n=1,2). ) are generally used on large diameter pipelines, as follows: * The Electric Tropics from one end of the pipeline wiring to the end of the end and then back to the starting point, the route equals coefficient. (but note maximum use length) * The Electric Tropics by the pipeline line one end to the tail end turns the wiring number equal to the coefficient. * back-up system, critical piping for back-up emergency. Therefore, each line should be installed independently of the line, and have a separate power point. | (vi) Fittings installation * According to the design requirements of the selection of accessories. * The sealing ring needs to be compatible with the electric tropics and waterproof sealing adhesive. * Power supply junction box as close as possible to the pipeline power supply side. * According to the installation instructions to prepare the line mouth. * A small section of the electric Tropics should be reserved at each end of the line for future maintenance. (vii) Inspection and testing of insulation materials before installation * Inspect the surface damage of the electric tropics. * Inspect all fittings for complete installation. * With the Shaking table 2500VDC to try each independent line at one end, insulation resistance should be above 20mω. Note that the shaking test time should be more than one minute, that is, conductive body to the electric tropical metal shielding layer to shake. * The test results are recorded on the installation record sheet. (eight) insulation layer installation Electric Belt Construction test immediately after the insulation layer installation, and attention to the following points: * The material, thickness and specification of the insulating layer are in accordance with the design drawing requirements. * The insulation material must be dry during construction. * Waterproof cover should be added outside the insulation layer. * Heat preservation layer should avoid damage to the electric tropics. * Insulation test shall be carried out immediately after the construction of insulation layer. * In the insulation layer plus warning labels marked "internal electric tropical" more need to indicate the location of all accessories. (ix) Low temperature start-up and safety protection: Electrical heat tracing engineering generally according to the design plan under normal circumstances, group start, according to the conventional control projection, with switch starting, overload protection and leakage protection, if used for low-temperature high-power heating, at the same time starting at low temperature, the instantaneous starting current into high-power output can be used to switch the dual switching device and in the switching process to monitor the operating current To transition to an overload protection system in the case of a security load. (10) Explosion-proof: * The company explosion-proof electric tropical can be used for factory one zone, two explosion-proof occasions, installation should avoid inflammable and explosive gas or liquid accumulation of dark angle may exceed the above provisions of the explosion-proof zone, the non-explosion-proof distribution box should be installed in the non-explosion-proof zone, or should be * In addition to explosion-proof grade, should pay attention to explosion-proof group. (11) Special precautions * Strictly prohibited steam with heat and electrical tracing mix used in one. * Add tropical installation should not damage the insulating layer, should be close to the heated body to improve thermal efficiency, if the hot body is non-metallic body, the use of aluminum adhesive tape to increase contact heat transfer area, with Niyoza belt fixed, strictly prohibited with wire lashing. * The flange of the media is easy to leak, winding electric tropical should avoid its directly below. * Electric heating one end of the power supply, the other end of the line is prohibited short or contact with conductive materials and cut to "V" type, must use a matching seal head tightly. * Explosion-proof junction boxes and terminals should be equipped for fire and explosion protection occasions. After wiring application of silicone rubber seals: (Use the shielding layer of the electric tape terminal must be stripped of the shield layer 10 cm, in case of a short circuit) * Install a hot spot, measure the insulation, the shielding layer must be grounded, insulation resistance can not be less than 20 trillion euro/1000v. * According to the electric heating each road voltage, current and other parameters set pass, power off and leakage protection devices. * Steam Sweep Line: where the need for steam cleaning pipeline descaling, should pay attention to the first cleaning after the installation of the Electric Tropics, if the annual routine sweep inspection should be in accordance with special circumstances design installation. (12) Acceptance: This manual does not include the installation of construction and acceptance requirements and the "explosion-proof, fire code" in the relevant provisions, the construction should be followed by the above-mentioned technical standard requirements, do not repeat. |